Introduction

For Underground Mine Ventilation Engineers, the longwall face presents a constant juggling act: how do you aggressively suppress the respirable dust generated by the shearer and conveying systems without compromising the vital airflow needed for methane dilution? It’s a challenge that sits at the heart of both safety and productivity in underground mining.

Quick Takeaways

- Effective longwall mining dust control airflow requires balancing dust suppression with essential ventilation for methane dilution.

- Optimizing water spray systems with appropriate nozzles and pressures is crucial for capturing respirable dust without hindering airflow.

- Strategic airflow management, including face velocities and ventilation infrastructure, is vital for removing airborne dust and methane.

- Spraying Systems offers tailored dust control solutions, including expert system design and site-specific optimization services.

- Continuous monitoring and maintenance of dust control and ventilation systems are essential for sustained effectiveness and regulatory compliance.

- Investing in integrated dust and airflow management systems offers a strong ROI through improved safety, efficiency, and reduced risks.

Research Summary

Underground Mine Ventilation Engineers face the critical task of harmonizing dust suppression and ventilation to ensure both safety and productivity in longwall mining operations. As this discussion has highlighted, a piecemeal approach is insufficient. True success lies in adopting integrated strategies that carefully consider the interplay between dust generation, optimized spraying technologies, and effective airflow management.

By investing in well-designed and diligently maintained dust control and ventilation systems, mines can achieve a significant return. This includes not only safeguarding the health of their workforce and adhering to stringent regulations but also enhancing operational efficiency and minimizing costly downtime. For Ventilation Engineers seeking to navigate these complexities and implement cutting-edge solutions, connecting with experienced providers is a crucial step. Explore the possibilities of tailored spray systems and expert optimization services to transform the challenges of longwall dust control into opportunities for a safer, healthier, and more efficient mining environment. Reach out to industry specialists today to discover how integrated dust and airflow management can benefit your operations.

The Critical Balance: Dust Suppression vs. Ventilation

Understanding Dust and Airflow Interactions

The interplay between dust and airflow in a longwall environment is complex. Think of it this way: the very act of mining liberates fine coal particles into the air. While water sprays are a primary defense, improperly designed or positioned sprays can introduce excess moisture, potentially increasing humidity levels in the mine or even hindering airflow if not optimized. Conversely, the ventilation system, while crucial for carrying away methane and other gases, can also pick up and redistribute dust if airflow patterns aren’t carefully managed. High air velocities, while beneficial for gas dilution, might also reduce the settling time of dust particles, making them harder to capture. Understanding this delicate dance between the generation, suppression, and movement of dust is paramount for effective underground mine dust suppression.

Consider a scenario where a mine increases ventilation to meet stricter methane regulations without adjusting its dust suppression system. The increased airflow might actually entrain more fine dust, leading to higher respirable dust concentrations downwind, even if the initial dust generation at the face remains the same. This highlights the need for an integrated approach where both dust control and ventilation are considered holistically. The goal isn’t just to apply more water or move more air, but to strategically use both to create a safer and healthier working environment.

Why Longwall Dust Control is Uniquely Challenging

The longwall mining method itself presents unique hurdles for dust control. The continuous movement of the shearer, the collapsing of the gob area behind the face, and the sheer volume of coal being extracted all contribute to significant dust generation. Unlike other mining methods with more localized dust sources, the longwall face is a dynamic and extensive dust-producing zone. Moreover, the confined space and the need to maintain consistent longwall face ventilation add layers of complexity.

Imagine a longwall face stretching hundreds of meters. Effectively delivering dust suppression agents like water sprays across this entire span, ensuring adequate coverage without saturating the coal or impeding the movement of machinery, requires careful engineering. Furthermore, the ventilation system must be designed to sweep across the face, capturing and carrying away both dust and gases without creating turbulence that could redistribute dust into worker areas. The geology of the coal seam, the cutting speed of the shearer, and even the humidity of the intake air can all influence dust generation and behavior, demanding flexible and adaptable control strategies. It’s not a one-size-fits-all situation, which is why a deep understanding of the specific challenges of longwall ventilation optimization is crucial for success.

Key Strategies for Integrated Dust and Airflow Management

Optimizing Spray and Nozzle Systems

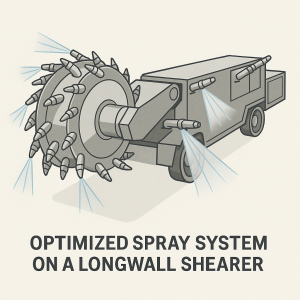

The workhorse of dust suppression at the longwall face is the water spray system. However, simply spraying more water isn’t the answer. The key lies in optimizing spray and nozzle systems to generate the ideal droplet size and spray pattern for capturing respirable dust while minimizing the impact on airflow. Different types of nozzles, from hollow cone to flat fan, produce varying droplet sizes and spray angles. Selecting the right nozzle for specific locations on the shearer, conveyor, and along the face is critical.

Consider a scenario where a mine implements a new shearer with poorly positioned or inappropriate spray nozzles. Instead of effectively capturing the dust at the source, the sprays might create a fine mist that hangs in the air, potentially obscuring visibility and even increasing the overall respirable dust concentration in the worker’s breathing zone. By contrast, a well-designed system utilizing dust control nozzles mining with optimized droplet sizes (typically in the 50-200 micrometer range for effective capture of respirable dust) and strategically directed sprays can significantly reduce airborne dust without adding excessive water to the environment. Furthermore, features like anti-clogging designs are essential for maintaining consistent performance in the harsh mining environment.

Airflow Management and Best Practices

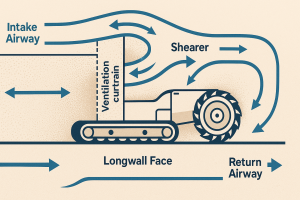

While water sprays aim to suppress dust at its source, effective airflow management and best practices are crucial for capturing and removing any remaining airborne particles and preventing their spread. This involves careful consideration of face air velocities, the placement of ventilation curtains and brattice, and the overall mine ventilation network.

Imagine a longwall face where the intake air velocity is too low. While this might seem beneficial for reducing dust entrainment, it can also lead to inadequate methane dilution, creating a serious safety hazard. Conversely, excessively high air velocities, particularly if not properly directed, can stir up settled dust and reduce the effectiveness of water sprays by causing droplets to evaporate too quickly. The sweet spot often lies in maintaining face velocities within a specific range (as indicated by research) and utilizing ventilation controls to direct airflow effectively across the face, pushing contaminated air towards the return airway. Implementing best practices such as regular maintenance of ventilation infrastructure and adjusting airflow patterns based on the advancing face are also crucial for sustained dust and gas control. This integrated approach ensures that methane dilution airflow mining requirements are met while simultaneously minimizing worker exposure to respirable dust.

Spraying Systems Solutions for Longwall Dust Control

Tailored Nozzles and System Design

At the heart of our dust control offerings are our tailored nozzles and system design expertise. We don’t just provide off-the-shelf components; our engineers work closely with mine operators to understand the specific dust generation characteristics and ventilation requirements of their longwall faces. This collaborative approach allows us to recommend and design spray systems that utilize the most appropriate nozzle types, spray patterns, and pressures for optimal dust capture with minimal impact on airflow. Whether it’s specialized nozzles for the shearer drum, face conveyors, or entryways, our focus is on delivering targeted dust suppression where it’s needed most. We consider factors like water availability, potential for clogging, and the need for durability in the harsh mining environment to engineer robust and reliable systems.

Site-Specific Optimization Services

Recognizing that conditions can change as the longwall face advances, site-specific optimization services are a crucial part of our offering. Our experienced engineers can visit your mine site to assess the performance of your existing dust control systems and ventilation strategies. Using advanced diagnostic tools and their deep understanding of respirable dust control longwall challenges, they can identify areas for improvement and recommend adjustments to nozzle placement, water pressure, and spray timing to enhance dust capture efficiency without hindering airflow. This iterative optimization process ensures that your dust control measures remain effective and aligned with your ventilation goals over the long term.

Long-Term Maintenance Support

Maintaining the effectiveness of dust control systems requires ongoing attention. That’s why long-term maintenance support is an integral part of our commitment to our clients. We provide guidance on regular inspection and maintenance procedures for our nozzles and systems to ensure consistent performance and prevent downtime. Our team is also available to provide technical assistance and troubleshooting support, helping you address any challenges that may arise and ensuring the longevity and reliability of your optimized dust suppression systems.

Operational Considerations

Monitoring and Maintenance

Continuous monitoring and maintenance of both dust control and ventilation systems are essential. Regular dust sampling and analysis provide valuable data on the effectiveness of current suppression measures. Tracking airflow velocities and patterns ensures that ventilation remains adequate for methane dilution and dust removal. This data-driven approach allows for proactive adjustments to be made before issues escalate. For example, if dust monitoring shows an increase in respirable dust levels downwind of the shearer, it might indicate a need to adjust spray patterns or increase water pressure. Similarly, regular inspection and maintenance of spray nozzles are crucial to prevent clogging and ensure consistent performance. Neglecting maintenance can lead to decreased dust suppression efficiency and potentially require more drastic and costly interventions later on.

Regulatory Awareness

Staying informed about and compliant with relevant regulatory awareness, such as those set forth by MSHA (Mine Safety and Health Administration) in the United States, is paramount. These regulations often specify permissible exposure limits for respirable coal dust and mandate certain dust control measures. Understanding these requirements and ensuring that your dust control and ventilation strategies align with them is not just a legal obligation but a fundamental aspect of ensuring a safe working environment. Furthermore, being aware of industry best practices and advancements in dust control technology can help mines go beyond mere compliance and strive for continuous improvement in worker health and safety. This might involve exploring new nozzle technologies, innovative ventilation techniques, or real-time monitoring systems that offer a more proactive approach to dust management.

Frequently Asked Questions

Q: What is the ideal balance between dust suppression and ventilation in longwall mining?

A: The ideal balance in longwall mining involves aggressively suppressing respirable dust at its source using optimized water sprays while maintaining sufficient airflow for methane dilution and removal of any remaining airborne particles. This requires an integrated approach where both dust control and ventilation systems are carefully designed and managed to work in concert, preventing increased humidity or dust redistribution.

Q: How can optimizing spray and nozzle systems improve longwall dust control?

A: Optimizing spray and nozzle systems involves selecting the right type of nozzles (e.g., hollow cone, flat fan) that produce the ideal droplet size (50-200 micrometers) and spray pattern for effectively capturing respirable dust at its source (shearer, conveyor) without using excessive water that could hinder airflow or saturate the coal. Properly designed and positioned dust control nozzles mining are crucial for minimizing airborne dust concentrations.

Q: Why is airflow management a key component of longwall face ventilation?

A: Effective airflow management is crucial for capturing and removing any dust not suppressed at the source and preventing its spread. Maintaining appropriate face air velocities, utilizing ventilation controls like curtains and brattice, and ensuring proper airflow across the face towards the return airway are essential for both dust removal and meeting methane dilution airflow mining requirements.

Q: What are the benefits of site-specific optimization services for dust control in mines?

A: Site-specific optimization services involve experienced engineers assessing existing dust control and ventilation strategies at a mine site. Using diagnostic tools and their understanding of respirable dust control longwall challenges, they can identify areas for improvement and recommend adjustments to nozzle placement, water pressure, and spray timing to enhance dust capture efficiency while maintaining optimal airflow.

Q: Why is continuous monitoring and maintenance important for longwall dust control and ventilation systems?

A: Continuous monitoring and maintenance of dust control and ventilation systems are essential for ensuring their ongoing effectiveness. Regular dust sampling and airflow monitoring provide data for proactive adjustments. Consistent inspection and maintenance of spray nozzles prevent clogging and ensure consistent performance of optimized dust suppression systems, contributing to a safer working environment and regulatory awareness.

Conclusion: Safer, More Efficient Longwall Operations

For Underground Mine Ventilation Engineers, the pursuit of optimal dust control in longwall mining is inextricably linked to the goal of safer and more efficient operations. By recognizing the critical balance between dust suppression and ventilation, and by implementing integrated strategies and leveraging advanced technologies, mines can achieve both improved air quality and enhanced productivity.

The ROI of Integrated Control Systems

The investment in well-designed and maintained dust control and ventilation systems yields a significant ROI of integrated control systems. Beyond the ethical imperative of protecting worker health and preventing respiratory diseases like black lung, effective dust management can lead to reduced equipment downtime due to dust contamination, improved visibility and thus increased operational efficiency, and a lower risk of regulatory fines and legal liabilities. Moreover, a healthier and safer working environment can contribute to improved morale and reduced employee turnover. By taking a holistic approach that considers the long-term benefits of investing in optimized dust and airflow management, mines can create a more sustainable and profitable operation.

Connect with Spraying Systems Dust Experts

Navigating the complexities of longwall dust control and ventilation requires specialized knowledge and experience. At Spraying Systems, we are committed to partnering with Underground Mine Ventilation Engineers to provide tailored solutions that address their unique challenges. Our team of experts is ready to help you design, implement, and optimize dust control systems that strike the perfect balance with your ventilation requirements. Connect with Spraying Systems dust experts today to explore how our innovative nozzle technologies, system design expertise, and ongoing support can contribute to a safer, healthier, and more efficient longwall mining operation. Let us help you turn the challenge of dust control into an opportunity for operational excellence.

We’d Love Your Feedback

What are your biggest challenges in managing dust and ventilation in your longwall mining operations? Share your experiences and let’s discuss potential solutions!

Leave a Reply